At PERON Automotive, our in-house manufacturing, led by our engineering division and turbo system specialists, Nortech Performance, is the culmination of our world-class research and development efforts. Identifying key needs within the performance aftermarket space, we manage every aspect of the process—from initial concept and design to simulation, testing, and final manufacturing—ensuring that each product is tailored for maximum impact and reliability.

Advanced Manufacturing

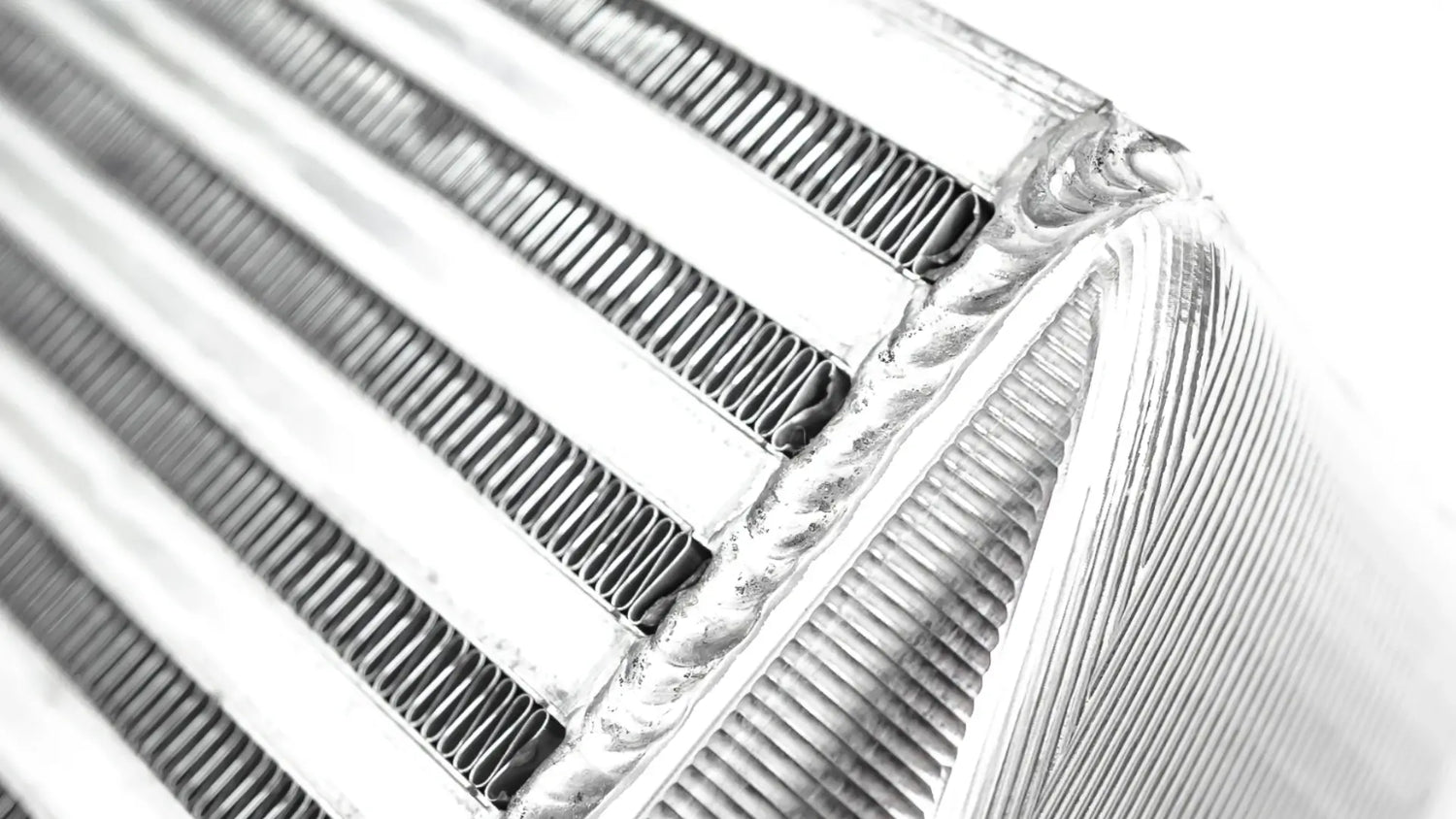

Cutting-Edge Manufacturing Techniques

Precision Engineering for Unmatched Quality