PERON and our engineering partners have a history of success with the EA113 engine in the PQ35 chassis, and this 8J TTS is a prime example that can match almost any modern car on the road. Our team are masters of the EA113 engine, having tuned this platform since 2005 across a range of applications. This extensive experience is why customers trust us to take their vehicles to the next level. Our commitment to pushing the boundaries of performance and drivability ensures each upgrade meets the highest standards of engineering excellence. This case study showcases our ability to transform the Audi TTS (8J) into a high-performance machine that excels in both everyday usability and spirited driving.

Case Study | Audi TTS (8J)

The Brief

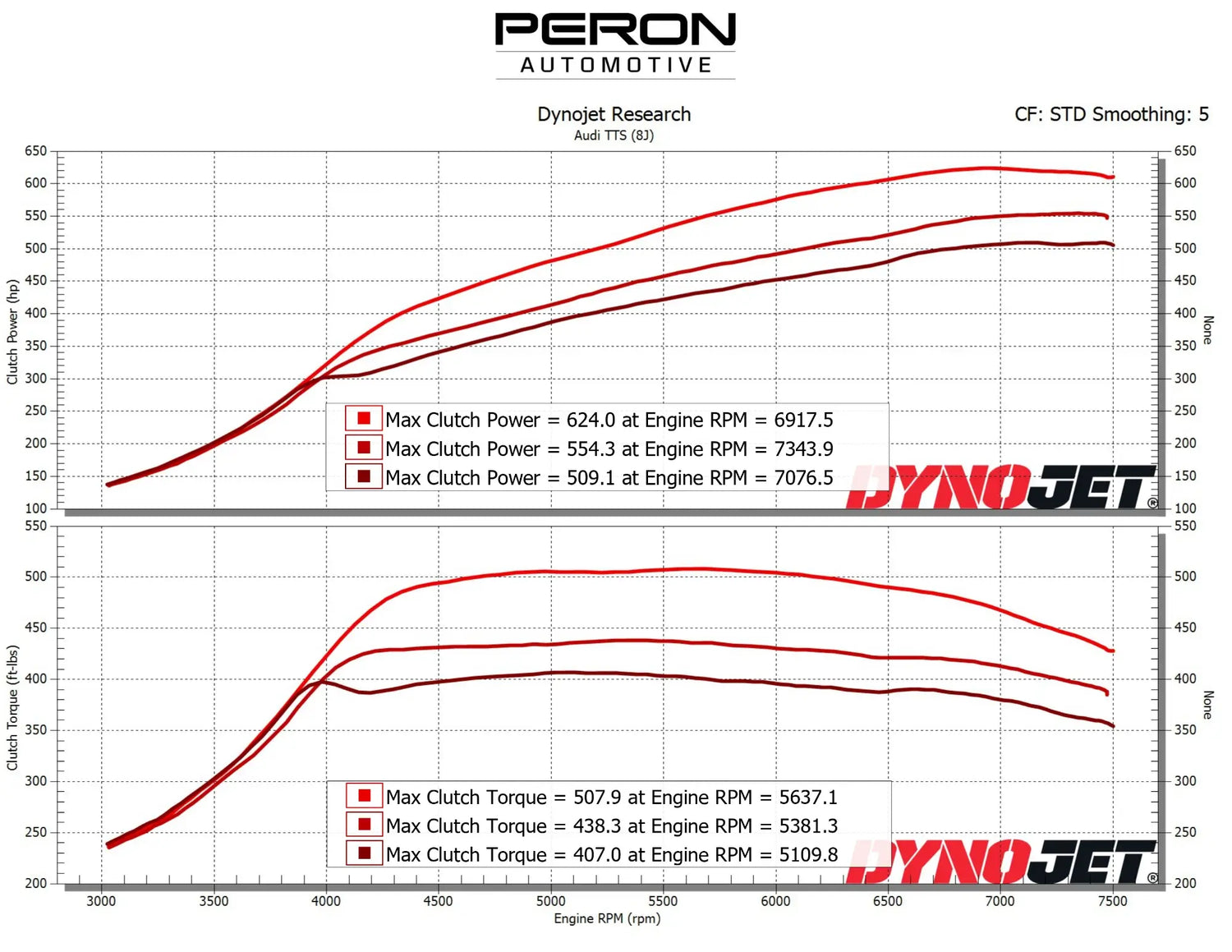

Our Results

Fuel System Upgrades

Engine Built for Durability and Performance Includes:

Engine Control Unit Calibration (ECU)

Transmission Control Unit Calibration (TCU)

Limits of the Platform

Contact PERON Performance

With years of experience across a wide range of applications, PERON Automotive is at the forefront of VAG tuning. Our approach is characterised by a narrow and deep focus on these platforms, combined with an unwavering obsession for excellence. Leveraging our advanced research and development centre, complete with an in-house dyno, we lead, validate, and support the performance aftermarket.

Partnering with the global best in ECU/TCU tuning and performance hardware, including our in-house Nortech Performance division, we deliver comprehensive tuning solutions that are proven both in our facilities and on the track. Contact PERON to discuss your upgrade path and learn more about how we can transform your vehicle.